BENEFITS OF MEP SHOP DRAWINGS FOR BUILDING CONTRACTORS.

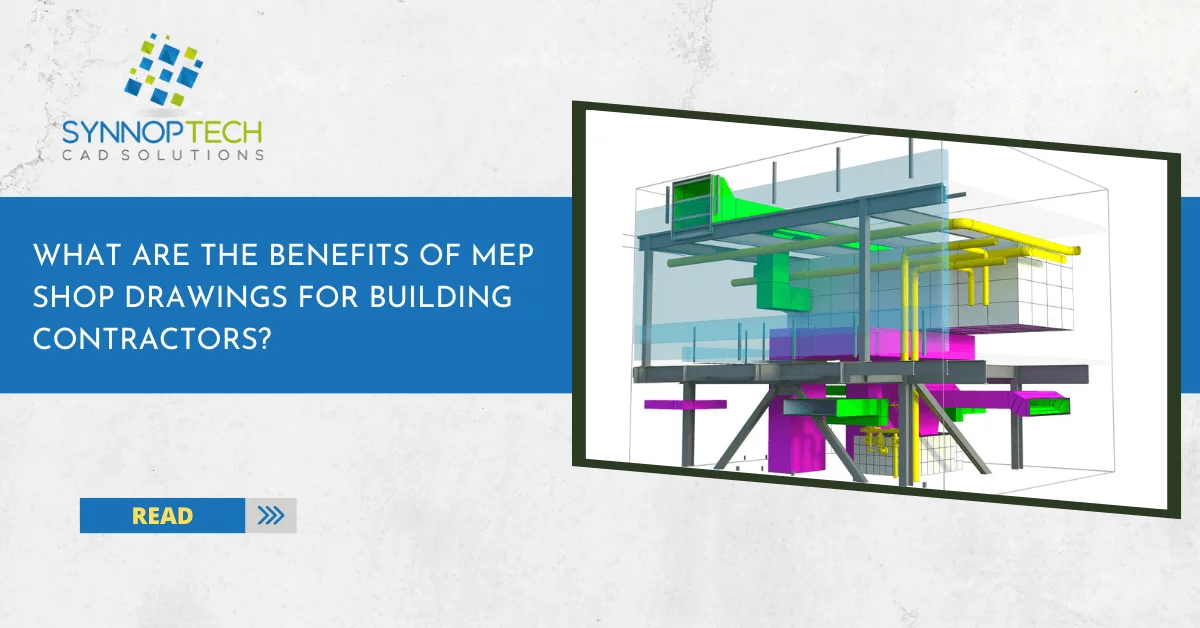

● Shop drawings for the MEP systems can be created directly from the model, ensuring flawless assembly.

Contractors can improve the quality of their MEP work by using information extracted from detailed shop drawings. Contractors can see MEP components from every direction thanks to thorough detailing, annotation, and tagging for representation and final assembly. General contractors can use this capacity to improve return on investment (ROI) by shortening the time required for installation at the job site and cutting costs.

● Better representation of design intent and visuals

Design goals are essential specifics that need to be attended to in the preliminary design or pre-construction phases. Standardized codes allow for a more clear depiction of an MEP layout and its components, giving MEP engineers and specialists more leverage in the design process. Coordinated MEP shop drawings to catch discrepancies before using the precise dimensions of the manufactured parts, and coordinated MEP shop drawings can prevent on-site errors from occurring.

● Strategic allocation of funds based on exhaustive knowledge of MEP parts

For large, complex building projects, accurate accounting of mechanical, electrical, and plumbing (MEP) components or systems is essential for efficient cost planning. When it comes to providing realistic estimates for the cost of MEP parts, general contractors face a number of obstacles. Mechanical, electrical, and plumbing (MEP) shop drawings are a reliable way to calculate the total amount of money spent on fabrication materials.

● Make use of MEP libraries to ensure consistency in your products.

Better accuracy is achieved when project specifications are combined with a comprehensive data set of MEP libraries used for modelling and creating 2D shop drawings. Using customized MEP libraries allows for the simulation of real-world functions while also ensuring high quality, a quick turnaround, and costs that are within budget. Improved coordination through the use of integrated workflows provided by MEP BIM models

The MEP models that are used in construction are the result of extensive collaboration between many different trades. Better documentation and outcomes for construction can be achieved for stakeholders with the help of a single 3D MEP model that is coordinated and clash-free. The on-site installation of MEP systems is made simpler thanks to integrated workflows that are implemented during the early design phase. These workflows ensure that general contractors receive accurate and high-quality deliverables.