Product Design and Development Company

SynnopTech CAD Solutions is a multi-discipline engineering Services Company serving industries like oil & gas, petrochemicals, metal fabrications, furniture and millwork, etc. We provide solutions that capture every part of your product design and build through better manufacturing documents starting from Scan to CAD, hand-drawn sketches, reference pdf drawings, CAD models, etc.

We take your product ideas and transform them into final designs, optimising each phase of development from concept through digital prototype and manufacturing inspection while adhering to norms and best practices throughout the process. We expect that product performance will eliminate the need for several physical trials, resulting in a reduction in associated expenses and an improvement in time to market for the product. We work with a range of high-end CAD tools, including AutoCAD, Inventor, SolidWorks, Creo, CATIA, Solid Edge, and NX, that helps us in improving productivity and efficiency in your product development process.

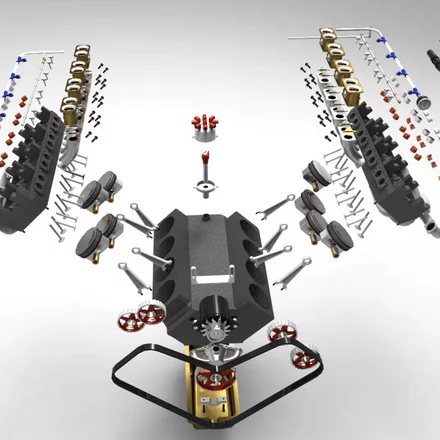

3D Product Modelling Services

We help you enhance virtual visualisation to look real, allowing you to see your products in greater depth and at a lower cost. Pre-fabrication visualisation can protect you from manufacturing defects, allowing you to solve problems imaginatively in a virtual environment. 3D models are created with real fabrication level deliverables, including many design variations, and bespoke component creation, with fabrication level requirements. Our expert engineers are well versed with international standards such as ISO, DIN, etc. and could adhere to any design standards along with maintaining the required geometric tolerances.

Shop Drawings Services / Fabrication Drawing Services

Shop drawings services are essential to avoid any misunderstandings or discrepancies and keep the design and its bespoke components up to date while avoiding manufacturing ability concerns throughout manufacturing. We provide a complete drawing with a material part lists (BoM/BOQ) that identifies the various materials, cutting lengths, and material orientation as the first or third angle of projection. We use the most up-to-date software technologies to deliver a complete set of fabrication drawings, including 3D modelling. Our experts have played an important role in the smooth completion of many product designs and construction projects, saving our clients time and money.

Photorealistic Rendering Services

We use CGI inspiring quality to render and portray the product in the greatest possible way by creating high-resolution photorealistic rendered images from 3D models and CAD files. Photorealistic Rendering Service is useful for achieving effects on a photograph as close to reality as possible. Our expertise is widely appreciated in the architecture and mechanical modelling fields. Our process includes Design planning, drafting, 3D modelling, and creating rendered animations and walkthroughs. 3D Interior Rendering, 3D Exterior Rendering, 3D Floor Plans, and Birds Eye View, our Photorealistic 3D Rendering Services enable the error-free depiction of any product or property.

Design Validation Service

The final chapter of any design or concept is testing and validating, our in-house design validation team makes sure that our product matches the required specifications of designs. We have FEA and CFD engineers with expertise in Static Structural Analysis, Vibration Analysis, Fatigue Analysis, Thermal Analysis, Seismic Analysis, Aerodynamic Analysis, Heat Transfer Analysis, Multi-phase flow Analysis and many more. Our experts are well versed with advanced software like ANSYS, OpenFoam, etc. to conduct Finite Element Analysis and Computational Fluid Dynamics simulations.

Design validation testing guarantees that the product satisfies the specified specifications. Companies anticipate combining product design and robust testing procedures. The high expense of re-spins and delayed tape-out can result in a significant competitive disadvantage. Thus, high-quality design validation and industry-specific requirements are required. To assure testing effectiveness, we use well-defined procedures and processes to undertake design validation services and compliance testing for product components.

Industries We Serve

Oil Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing